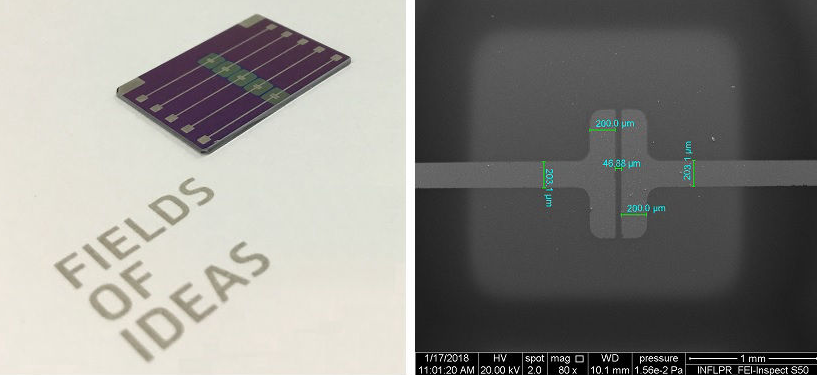

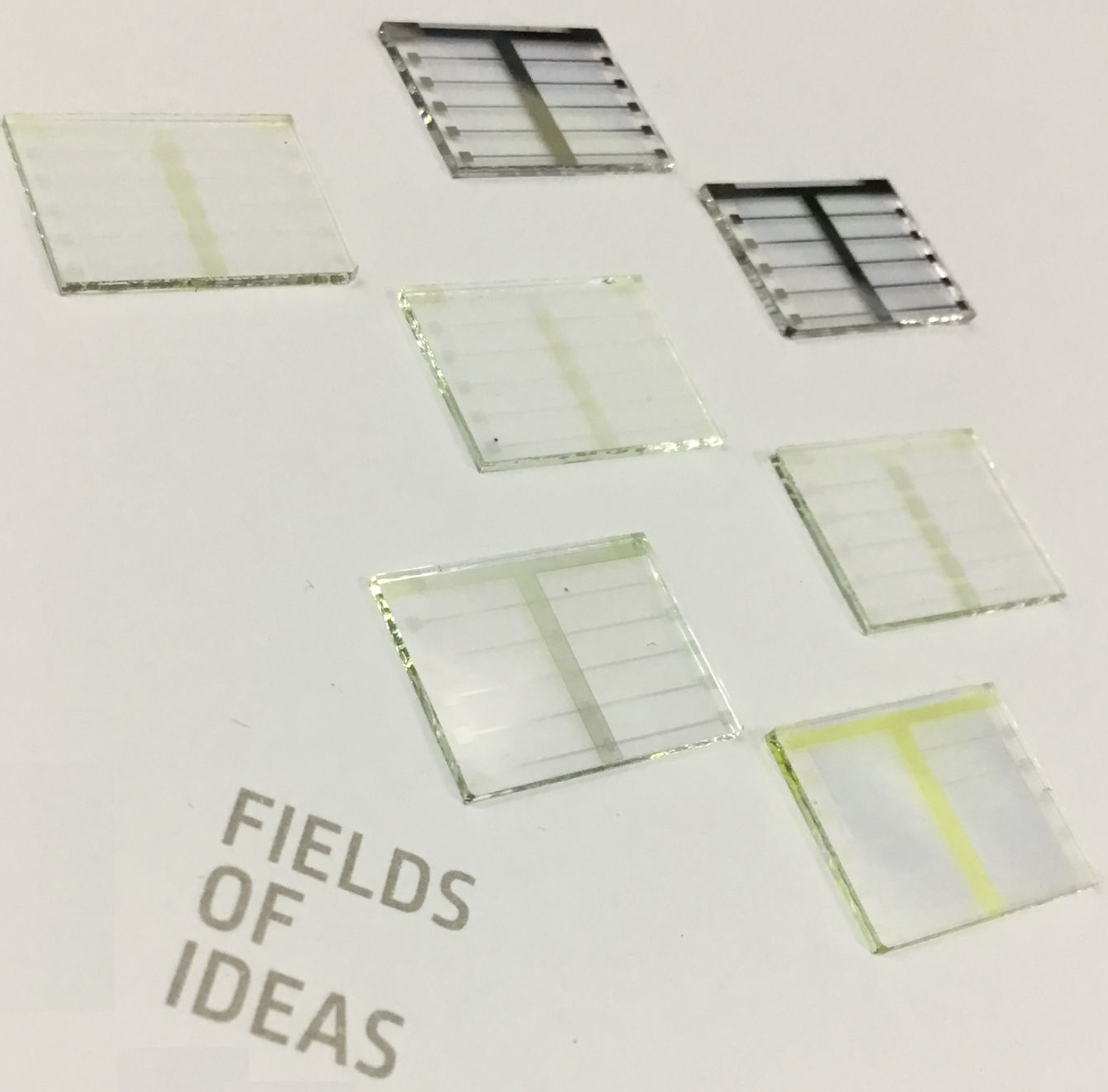

We fabricate our sensing devices using metal oxides and low-cost substrates such as glass or oxidized silicon. Semiconductor metallic oxides are globally among the most researched and most promissing materials for gas sensors, transparent and flexible electronics.

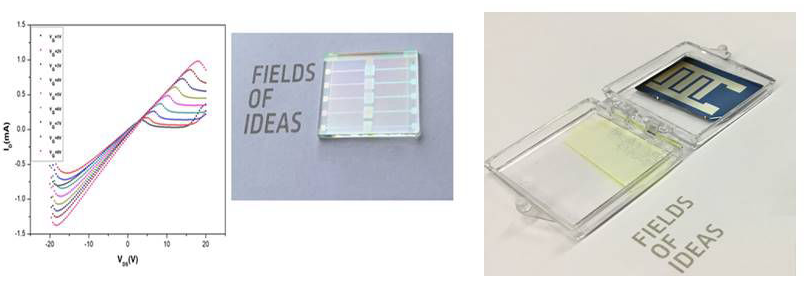

LEFT: A structure of five miniature conductometric gas sensors fabricated on oxidized silicon. RIGHT: A SEM image of the central area of one of the sensors in the structure. The film of metal oxides has an area of 4sq.mm, while the space between the Pt electrodes is around 40microns.

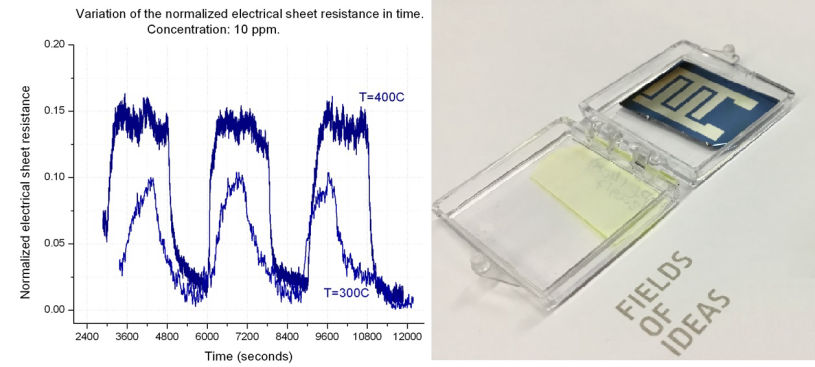

In the context of a global transparent electronics market estimated to reach 5.1 billion EUR in 2018, we are actively following the latest trends and have extended our research towards transparent TFT based gas sensing devices. TFT sensing devices exhibit important advantages over the conductometric sensors such as increased selectivity, better accuracy and precision in detection (higher sensitivity and lower detection limit due to the transistor effect), increased dynamic range and reversibility. These devices have higher signal to noise ratios than chemiresistors, longer lifetime, lower response times, diminished temporal drift and lower operating temperature range (closer to room temperature). TFT based gas sensors are mostly employed to detect reducing gases like hydrogen, CO, hydrocarbons and vapors of organic solvents.

According to the EU regulations, CO has an occupational limit value of 20ppm (TWA), hence sensing devices should address concentrations below this limit. Currently, the majority of commercial indoors CO sensors on the market are able to detect only concentrations of over 75ppm. Prerequisites for outdoor systems (pollution monitors) demand accurate measurements of concentrations below 5ppm as CO background levels for the outdoor environment normally fall within the range of 40 to 200ppb.

Nanostructured sensitive layers are known to boost the gas sensing performance of conductometric sensors. For this purpose we are using electrochemical anodization as a convenient and efficient way of obtaining a surface covered in metallic oxides nanotubes. Common metals such as Zn, Fe, Ni, Nb, Sn, Al and and their alloys can be anodized without any special requirements. We have successfully managed to grow nanotubular structures of TiO2 on Ti substrates as well as on Ti-6Al-4V grade 5 alloy (along with the corresponding aluminum and vanadium oxides) using the same Keithley 2450 SourceMeter SMU instrument. Alternatively, an OrigaStat OGS100 instrument (potentiostat, galvanostat and impedance meter) specially designated for electrochemistry is also available in our lab.